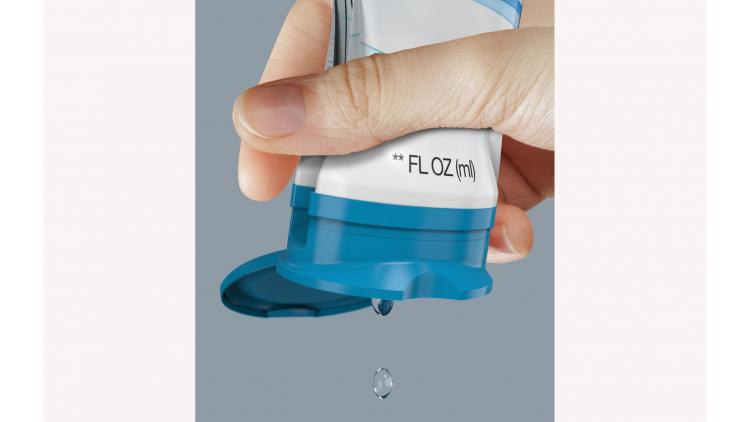

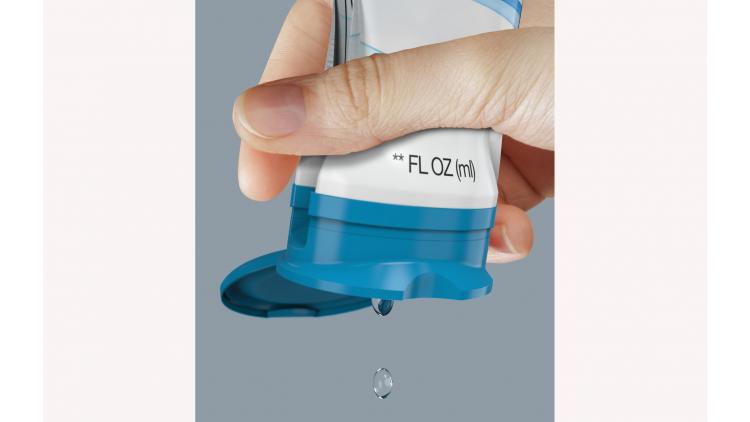

Pro Pouch Squeeze, ProAmpac’s entry in the inverted pouches market for foods, personal care and other categories, is seeing a lot of interest.

ProAmpac has rich history of innovation in the flexible packaging market attributable to the lineage of the two forming companies, Ampac and Prolamina, from which it was shaped into an integrated whole in a 2015 merger.

That tradition continued about a year ago with the launch of the PRO POUCH Squeeze inverted pouch that’s the focus in this second of Packaging Digest’s ongoing series about this on-trend, convenience-centered format (see Inverted pouch trend upends food packaging: Chobani, published December 2018).

Sal Pellingra, vp global application and innovation development, ProAmpac, says the company’s Pro Pouch Squeeze can replace squeeze bottles as well as thicker tube packaging for both food and non-food packages, specifically liquid food and condiments, health and beauty and industrial chemical markets. He responds to our questions in this Q&A interview.

What’s the background and activity you’re seeing in this market?

Pellingra: We’re seeing a lot of interest in several markets based on the advantages of this package format. Because the ProPouch Squeeze doesn’t have side seals like other pouch solutions, it’s unusually soft and easy to hold and squeeze.

What do you see as the advantages and drivers for ProAmpac’s version of the inverted pouch?

Pellingra: For traditional squeeze bottles in haircare for shampoo and conditioners, condiments and industrial chemical products, ProPouch Squeeze provides many benefits including:

- It’s soft and easier to squeeze to get the product out of the container. Consumers often have to shake bottles to get the product to dispense and often can’t get all the product out of the package. This eliminates both issues. The product is always at the bottom, primed and ready and the package is easy to squeeze to get all the product out of the package.

- The packaging can be sealed on the top much easier than a typical polymer tube. Tubes are thick so it’s difficult to get heat from the exterior to the interior for sealing. Also, the seals may get a little messy so trimming is needed after that—steps that slow the filling line and reduce output. ProPouch Squeeze is like sealing a flexible package on the top so much easier to seal providing higher filling efficiencies.

- As a flexible package, there is tremendous opportunity to include a wide range of graphic treatments vs the typical front and rear face in-mold labels on rigid containers. ProPouch Squeeze can offer a wide range of 360-degree graphics eliminating spot graphics and in-mold labels. The package can really stand out on the shelf with photorealistic printing.

- Sustainability: this package will significantly reduce the amount of plastic used versus rigid or semi-rigid alternatives. It also reduces a bigger problem, product waste, by enabling consuemrs to get essentially all of the product out of the package.

- Global platform: because of its lower cost and improved functionality, these pouches offer brands a format that can be leveraged across geographies in emerging as well as in developed markets.

The interest in this format is growing as brands move ever forward to higher convenience, sustainability and cost savings.

What can you say about the structure and closure?

Pellingra: Structures are customizable depending on the product requirements, but we’re starting with polypropylene/polyethylene laminates in two or three layers depending on barrier needs, stiffness and tactile feel.

We’re working with PE-based fitment and cannot divulge the partner at this time.

These would be supplied as premade pouches, but could be form-fill-seal in the future. They would be filled with the opened flexible end opposite the fitment.

What’s the status?

Pellingra: We are currently working on potential opportunities with launch partners. There are a few different product applications so the filling machine partners may be different depending on the segment and type of product, whether food or non-food. In the same way we have a couple different fitment supplier partners depending on the product.

What’s the next step?

Pellingra: We’re actively working on a commercial application.

The website is ProAmpac.com

___________________________________________________________________________________

While presenting the latest solutions in automation, food packaging, package design and more, WestPack 2019 (Feb. 5-7; Anaheim, CA) provides access to the industry’s leading educational offerings with the 3D Printing and Smart Manufacturing Innovations Summits and free industry education at the Expo. Register to attend today! ___________________________________________________________________________________