ADLink Technology’s gamified booth at Pack Expo showed how artificial intelligence could be leveraged for optimized palletizing, IoT, metadata, WMS and ERP in replacing hand scanning.

The promise of gamification using artificial intelligence (AI) promoted as Interactive exhibit shows how packages and pallets can “talk” to each other with Edge IoT was an intriguing incentive to visit the booth of ADLink Technology during last fall’s Pack Expo in Chicago.

A preshow release indicated the demo was to show how the company’s ADLink Vortex Edge supports vision-based Internet of Things use cases throughout the distribution warehouse with a picking, packing and palletization setup.

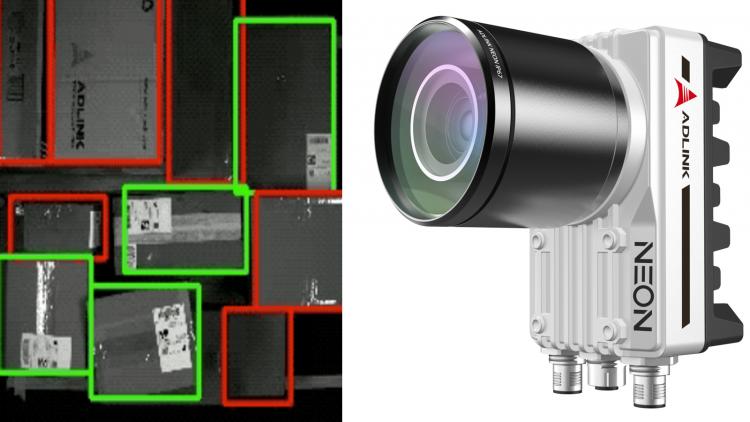

The setup involved an array of AI-enabled machine vision cameras mounted over the dual pallets that were to be loaded with boxes that the system processed as digitized corrugated shipping containers. A large monitor screen indicated to the operator, aka the game participant, if the box was on the proper pallet with a green or red indicator. All the gamer had to do was load a box onto a pallet and leave it in place if green and switch pallets if red.

Seeing it in action was an edutaining experience, both for observers and attendees trying to win a prize. But there’s serious technology behind the game-show-style thrills, which Dan Collins, director ADLink IoT North America, explains.

What’s the origination of the company name?

Collins: Our name, ADLink, is based on our expertise in linking the analog to the digital, hence the name A-D-Link. With ADLink Edge, we’re taking something as analog as a corrugated box and digitizing it. We’re generating information about the size, shape, and location of that box in 3D space and time, as well as data about the speed and accuracy of the pallet loading process. For instance, we have some clients using machine vision for smart pallets, while others are using the solution for parts picking, quality inspection, collision avoidance and even robots.

I was impressed by the interactive demo, but why use AI for manual palletizing—and can it assist automated setups?

Collins: Most distribution warehouses today still use hand-held scanners. The portable scanner does two things: it verifies that the package is on the right pallet, and it logs which packages are on which pallets for inventory. Even with the hand scanners, palletizing is a slow, human-intensive and error-prone process. Palletizing can only go as fast as the human operators. Critically, if a package is mis-scanned or not scanned at all (a “no-scan”), that package is effectively lost. It simply no longer exists.

Hand scanners perform one task: they read anything and everything you put in front of them, including markings you don’t want to scan. Hand scanners are also not ergonomically helpful—limiting the number of boxes a pallet loader can carry and requiring the loader to bend or kneel for scanning.

AI solves all of these issues. Using an Edge IoT machine-vision system like ADLink Edge frees up pallet loaders’ hands to carry more boxes, increases scan accuracy and can capture metadata about each package. That’s akin to creating a digital twin, so even if a package is missing a label or doesn’t get scanned at all, the box can still be identified on the pallet.

The ADLink Edge system demoed at Pack Expo, like all ADLink solutions, is configured for full automation.

What are the benefits for the customer and operators?

Collins: The benefit of AI for the customer is cost-savings and customer satisfaction. AI saves companies money by speeding the pallet loading process and reducing product loss through increased scanning accuracy. For example, one client of ADLink is a major pork processor where every minute counts as pallets are loaded for cold storage. The client’s highly perishable product must be loaded as quickly as possible, and inventory must be logged correctly so that product is pulled and shipped based on its storage date to prevent spoilage.

For clients with a high mix of packages on pallets (every package on a pallet may be for a different recipient) or who are shipping expensive items globally, ADLink Edge reduces product loss by accurately logging each package and pallet. For these clients, a mis-scan or no-scan can result in weeks of waiting to find out if the right package was delivered to the right customer and replacement costs that’s more than double what they’re charging their customer.

The benefit of AI for the pallet loaders is speed and ease of use. They don’t have to carry a hand scanner or anything else, freeing their hands to load more packages more quickly.

What is the specific nature of the AI for this?

Collins: ADLink Edge Smart Pallet is an Edge IoT hardware and software solution for machine vision. We install sensors and cameras above the pallet, so pallet loaders don’t have to learn how to use any new gadgets or programs or do anything, but simply load the pallet. As far as they’re concerned, we’re not even there. Our sensors and cameras are essentially on the ceiling, so their standard operating procedure of loading a pallet does not change at all, and that’s extremely exciting to them.

We also install a user interface, including lighting and sound, to give feedback to the pallet loaders. For instance, for one customer we installed red and green lights to highlight packages when they’re on the correct pallet and alert them when they’re on the wrong pallet.

On the backend, we can connect to literally anything. We integrate with any warehouse management system (WMS), enterprise resource planning (ERP), conveyor system, robotics, or any other system a company may be using, and then we “train” the AI to be able to identify, scan, and log packages and labels to our client’s specifications. With our tools, just about anybody can train the machine-vision applications using a drag-and-drop type method. We want to give the actual end users, the subject matter experts, plant managers, and distribution warehouse managers, a voice in the process, and these tools give them that.

What further AI activity do you expect in your installs and generally in packaging?

Collins: We see machine vision being used at every point of the process, throughout the entire distribution warehouse, and all the way back to the manufacturing. We already have clients using this same technology for a variety of different applications. Palletizing was just the overlooked “last mile” of the manufacturing and distribution process because people tend to think that process can’t be automated and/or that it’s too expensive. At the end of the day, this is just another machine-vision use-case.

In our minds, machine vision can solve all sorts of different use-cases that have never been thought of before, helping both humans and robots make better decisions. We’re trying to make any and all equipment intelligent; vision is just another way of doing it.

So, we are taking all sorts of different sensors, applying logic, AI if necessary, and making things smarter and more capable of understanding how to optimize themselves. We’re giving machines the ability to understand their health to trigger alerts about whether or not they require maintenance, to make decisions about whether to speed up or slow down to extend the life of equipment.

For our major pork processing client, for example, we’re giving intelligence to the chillers they have throughout the warehouse by installing a variety of sensors to monitor the warehouse as well as the chillers. With those sensors and AI, the chillers themselves are monitoring their own efficiency and making decisions like raising their temperature slightly to reduce the possibility of failure until the next scheduled maintenance.

What’s been the interest in AI?

Collins: Interest in the AI capabilities of ADLink Edge has been very high. We already had several customers before Pack Expo, and our “Gamification of AI” demo at Pack Expo was a huge hit for us. We drew a great crowd not only because of how we “game-ified” the pallet loading process for our demo, but also because everyone has the same issue with palletization: it’s either too slow or too inaccurate. Through the game-style demo, we were able to show people how fast and accurate the palletization process can be with a technology that’s very non-intrusive. They could see that we’re not changing anything about their actual pallet loading process. Since Pack Expo we’ve been actively engaged with over 40 different clients, many of whom are partnering on ADLink Digital Experiments, which is our approach to getting started with any of our solutions. Digital Experiments determine the lowest software and hardware costs that yield the highest return specific to a client’s particular situation, so they can be successful with their machine vision deployment.

What’s the most common question about the AI?

Collins: People ask how expensive it is and we often get questions about security.

AI is actually less expensive for this process than you might imagine. It has to be, because palletization is one of the leanest processes. So, we make it incredibly affordable—and it’s scalable. We design all of our solutions thinking two or three steps ahead, so a warehouse can install ADLink Edge now and easily go to full automation in the future with no need to rip-and-replace. It has a very long lifecycle as just one part of a fully automated distribution warehouse.

The other concern with security is usually centered on companies wary of their data being sent to the cloud. We specialize in the use of data at the edge. We can run machine vision AI at the pallet or even on the camera if we have to, and that eases a lot of concerns and fears since everything remains self-contained and secure at the customer site. We are not sending anything anywhere. Now, if the client wants us to send information or data to the cloud, we can certainly support that. But we are effectively selling a self-contained edge-based solution that does not require cloud connectivity. So, from a security perspective, that is a huge value-add.

What projects are you working on that our packaging audience would find of interest?

Collins: A couple interesting applications: we’re currently working with a client for packaging automation of cold storage meat pallets (lamb processing facility) helping them to improve their pallet manifest inventory, reduce spoilage, and load pallets faster. We’re also talking with a food manufacturer to help them determine the correct fill levels of each spice container (think cooking spices like basil, oregano, thyme, etc.) as they come down the filling line.

For more information, visit ADLink Technology