Once upon a time in 2018, a cobot manufacturer, a contract packager and Conagra all had compelling stories to tell of packaging production flexibility, optimization and sustainable performance.

Here, we present the top three packaging-production articles of the year, based on page views by the global Packaging Digest audience, who were held spellbound with dreams of greater productivity and ROI.

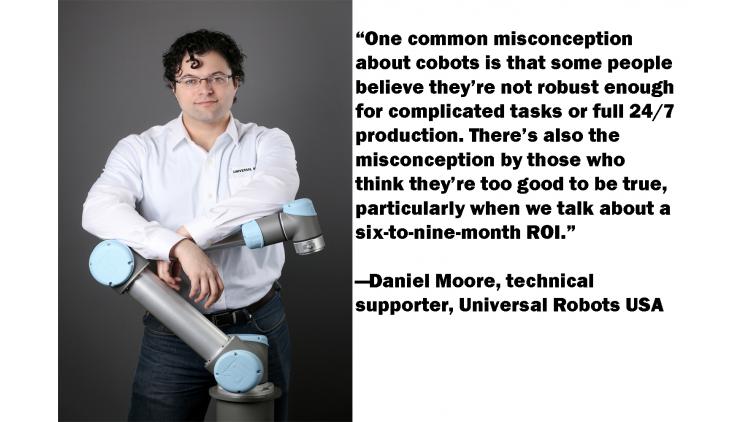

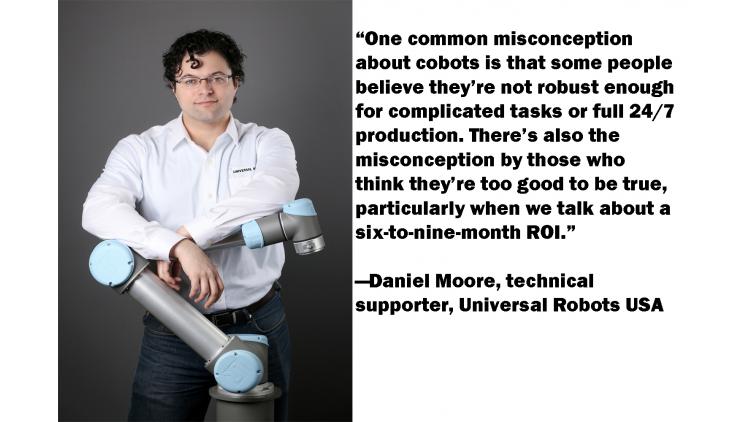

3. Cobots in packaging 2018: A debriefing with Universal Robots

As manufacturers struggle to fill open plant positions with humans—qualified or not—they’ve been eyeing other, more automated options.

Earlier this spring, robotics “insider” Daniel Moore, who specializes in technical support at Universal Robots USA Inc., gave a quick yet thorough update on the fast-growing automation sector of collaborative robots. Advancements in vision, networking, interfacing and design mean cobots today have more reach, more robustness, more ease of use and more expandability.

Moore believes we’re at the point where everyone can use and benefit from a robot, especially as the company focuses on helping even the smallest shops optimize production.

The sector’s rapid growth continues, as does Universal Robots’ business. The year ended on a happy note with the hiring of 20 employees from recently-defunct competitor Rethink Robotics for Universal Robots’ location in Boston.

2. Pouch filling operation sets new standard in quality, efficiency

A growing consumer acceptance for flexible packaging and a boost in viscous liquid products in pouches—such as baby foods and sports nutrition products—represents big business for contract packager Cascata Packaging. Our early 2018 case study highlights strengths in several areas as the company leverages current market trends, including:

A speed-to-market advantage that customers highly value;

On-shelf differentiation;

Enhanced user experience;

The Amazon-ification of food—that is, the growth of ecommerce for groceries;

Consumers looking for healthy/organic foods that are also convenient and shelf-stable (non-refrigerated).

1. How Conagra rewards packaging line workers for cutting waste

When you work hard, a sense of accomplishment—and a pat on the back—goes a long way in encouraging employees. But formal recognition is a nice incentive, too. That’s the idea behind Conagra’s Sustainable Development Awards, a contest started in 2009 that improves packaging operations by asking for ideas from the people who are on the plant floor working with the machines and packaging materials.

In this profile, Conagra’s vp of sustainable development Gail Tavill shares details of three packaging-related winners of the company’s 2018 Sustainable Development Awards:

1. The Slim Jim operation in Troy, OH, eliminated more than 500 tons of film waste annually by modifying the cutting assembly on the stick pack machine, which also allowed for quicker and less expensive repairs and reduce unplanned stops.

2. The David Seeds operation in Waterloo, Iowa, saved 225,000 bags of seeds a year by purging seven bags instead of the previous 10 during start up before reaching the correct residual oxygen level during nitrogen flushing.

3. The operation in Milton, Pa., achieved a 2% yield improvement (projected at $350,000) while reducing 1,150 tons of wasted sauce per year by adjusting the filler.